Friday, December 30, 2016

Follow our UAS Colleagues on Instagram

The Michael Baker International Unmanned Aerial Systems (UAS) team is now on Instagram! Our flight operations teams are going to post pictures to show off some of our work.

Thursday, November 24, 2016

Friday, November 11, 2016

Veteran’s Day

On behalf of Michael Baker International, the Mobile LiDAR Team would like to recognize and thank our veterans for faithfully protecting our freedom, as well as the active military members and their families who unselfishly serve this country.

As a firm that employs veterans from many countries and delivers mission-critical services in support of our country’s military across the globe, we’d like our active duty, reserve, guard and contractor friends and family to know they are in our thoughts during their extended deployments and separation from friends and families.

On this Veteran’s Day it seems only fitting to share this colorized point-cloud image of an F-18 Hornet from our Navy’s world-famous Blue Angles (celebrating their 70th anniversary this year), captured during a previous project as NAS Pensacola.

Thank You Veterans!

Mobile LiDAR Team

As a firm that employs veterans from many countries and delivers mission-critical services in support of our country’s military across the globe, we’d like our active duty, reserve, guard and contractor friends and family to know they are in our thoughts during their extended deployments and separation from friends and families.

On this Veteran’s Day it seems only fitting to share this colorized point-cloud image of an F-18 Hornet from our Navy’s world-famous Blue Angles (celebrating their 70th anniversary this year), captured during a previous project as NAS Pensacola.

Thank You Veterans!

Mobile LiDAR Team

Monday, October 24, 2016

Scrabble and LiDAR

Earlier this month I was on LinkedIn and read a posting on somebody’s page that LiDAR is now an official word in the Scrabble game’s dictionary. I guess that’s a good thing to know. For people that work with LiDAR or acquire the data from a service provider, you perhaps just got a slight edge over your board-game competitors. At least that’s true for those competitors that are not as LiDAR aware or informed as you.

In some respects, I’m still left at odds to think about “scrabble” and that word’s meaning in any context related to LiDAR. According to Merriam-Webster's Learner's Dictionary scrabble means to: “scrawl, scribble; to scratch, claw, or grope about clumsily or frantically; scramble, clamber; to struggle by or as if by scraping or scratching.” That’s sort of an incongruent meaning with the precise nature of the LiDAR systems we utilize and the projects we perform with Mobile, Aerial and Static LiDAR systems. Then again Scrabble is just a game and LiDAR is just a word of no particular importance in that game. Let’s move on.

What is important however, is that LiDAR is such a pervasive technology today that it’s become a common technology even to the layperson. LiDAR has far more usefulness in every day purposes than the mapping-grade systems we operate. LiDAR systems and their data are being deployed in ways that truly reaches the mainstream of our everyday lives. As we so well know, autonomous vehicles of all forms are being deployed with LiDAR capabilities for object detection and recognition and directional guidance.

So back to the subject of this blog, here is Michael Baker’s tribute to all those Scrabble players that will use “LiDAR” in their future games.

You’ll note that we’re also emphasizing some of the qualities on the game board that we feel are important to our LiDAR operations here at Michael Baker. We’re also displaying a HoloLens system and a UAS being on the table. The UAS is being evaluated by our Kevin Pomaski for potential future flight operations. We are already integrating Mobile LiDAR and panoramic imagery with UAS photography to create 3D data for immersive holograms using HoloLens.

With this in mind, it’s also my pleasure to re-introduce Kevin Pomaski to you. Kevin had worked at Michael Baker in the past and has rejoined us (a boomerang) to now provide his personal leadership to our UAS activities and the integration of converging technologies. We will continue to develop innovative solutions for project delivery. Kevin will soon be writing about some those amazing things he is doing while merging UAS data and Mobile LiDAR data, and creating HoloLens visualizations. Kevin will be adding his blog postings on these activities to this blog site in the coming weeks.

Finally, if you want some additional Scrabble tips for LiDAR, this is a pretty good site to learn what you can do with LiDAR in your next Scrabble competition: http://scrabble.merriam.com/finder/lidar.

Until, next time,

Bob Hanson

P.S.: Art Morris who leads IT support for our systems for LiDAR and UAS here at Michael Baker says those Scrabble tiles placed on the stand to the right have a very special meaning to “The Simpsons” fans.

In some respects, I’m still left at odds to think about “scrabble” and that word’s meaning in any context related to LiDAR. According to Merriam-Webster's Learner's Dictionary scrabble means to: “scrawl, scribble; to scratch, claw, or grope about clumsily or frantically; scramble, clamber; to struggle by or as if by scraping or scratching.” That’s sort of an incongruent meaning with the precise nature of the LiDAR systems we utilize and the projects we perform with Mobile, Aerial and Static LiDAR systems. Then again Scrabble is just a game and LiDAR is just a word of no particular importance in that game. Let’s move on.

What is important however, is that LiDAR is such a pervasive technology today that it’s become a common technology even to the layperson. LiDAR has far more usefulness in every day purposes than the mapping-grade systems we operate. LiDAR systems and their data are being deployed in ways that truly reaches the mainstream of our everyday lives. As we so well know, autonomous vehicles of all forms are being deployed with LiDAR capabilities for object detection and recognition and directional guidance.

So back to the subject of this blog, here is Michael Baker’s tribute to all those Scrabble players that will use “LiDAR” in their future games.

You’ll note that we’re also emphasizing some of the qualities on the game board that we feel are important to our LiDAR operations here at Michael Baker. We’re also displaying a HoloLens system and a UAS being on the table. The UAS is being evaluated by our Kevin Pomaski for potential future flight operations. We are already integrating Mobile LiDAR and panoramic imagery with UAS photography to create 3D data for immersive holograms using HoloLens.

With this in mind, it’s also my pleasure to re-introduce Kevin Pomaski to you. Kevin had worked at Michael Baker in the past and has rejoined us (a boomerang) to now provide his personal leadership to our UAS activities and the integration of converging technologies. We will continue to develop innovative solutions for project delivery. Kevin will soon be writing about some those amazing things he is doing while merging UAS data and Mobile LiDAR data, and creating HoloLens visualizations. Kevin will be adding his blog postings on these activities to this blog site in the coming weeks.

Finally, if you want some additional Scrabble tips for LiDAR, this is a pretty good site to learn what you can do with LiDAR in your next Scrabble competition: http://scrabble.merriam.com/finder/lidar.

Until, next time,

Bob Hanson

P.S.: Art Morris who leads IT support for our systems for LiDAR and UAS here at Michael Baker says those Scrabble tiles placed on the stand to the right have a very special meaning to “The Simpsons” fans.

Thursday, October 20, 2016

By the Numbers: Mobile LiDAR Processing

- 18: Number different software packages we use to collect and process Mobile LiDAR data.

- 1,000: Number of concurrent users that can access our LiDAR web-portal running Orbit Publisher. Michael Baker’s state-of-the-art portal enables clients to interact with their LiDAR, imagery, and planimetric data without the need of expanding their own enterprise architecture.

- 3: Number of primary LiDAR/LCMS processing centers in the U.S.: Hamilton, NJ; Pittsburgh, PA; and Jackson, MS.

- 90+: Number of domestic Michael Baker International offices our fleet of Mobile LiDAR systems supports.

- 10: Number of computers one LiDAR Technician can simultaneously operate to process data.

- 5: Number of Terabytes that can be transferred to our LiDAR Centers each day.

- 100+: Number of external hard drives in rotation between our fleet of 4 Mobile LiDAR systems and various processing centers.

- 50-200: Local capacity in available Terabytes at each of our LiDAR processing centers. The local storage is only used for short-term needs. Enterprise data storage processing is handled by our own private cloud (see Belly of the BEAST) which can handle up to 1 Petabyte of data.

Friday, October 14, 2016

Cultivating Excellence: Mobile LiDAR Operator Training

Success is not given for us, it is earned. For all of my team members in the LiDAR Center our success begins through the deployment of one or more of our Mobile LiDAR vehicles. Training new Mobile LiDAR operators is the most important aspect of the LiDAR Center’s daily successes. We have a saying within the LiDAR Center: “Our operators are the ones that actually drive our business.”

Our driver/operators are the tip of the spear for all of our Mobile LiDAR projects. With our increased work load, hiring and training operators has been paramount in recent months. These vehicles carry the LiDAR systems that create vast amounts of data. Effective field operations are the base of our entire operation. Without quality data every second of every day, a ripple effect is made all the way down the project’s product line.

Training begins typically on the new hire’s first day, with a multitude of training manuals, power points, and videos. Safety is our first priority in all our training. As Senior Operator, my job is to ensure our new hires know how to be safe while performing their work and flawlessly conduct every aspect of our collection tasks with our systems. All of this must be learned before they get in a Mobile LiDAR vehicle. It will take weeks to fully break down all of the necessary information presented to them. As we like to say, “It’s more than just pushing a button and driving.” Learning takes time and attention to all details. With daily experience they gain tremendous proficiency.

All aspects of our Lynx SG-1 system are introduced to them, from basic start up and operation, to troubleshooting and diagnosis. They learn how to adjust and calibrate the system, modify existing set ups to accommodate different equipment requirements, calculate scale factor, GNSS Azimuth Measurement Subsystem (GAMS) solution, etc. all in a short period of time. (If you wish to learn more about GAMS read an article written for LiDAR Magazine by our Stephen Clancy that may help you better understand the concepts and techniques for deriving positions from the equipment and software associated with Mobile LiDAR systems.)

Training will continue even after new operators have gleaned all they can out of their training manuals. Being in a Mobile LiDAR truck and performing a collection is an entirely different animal than being in a classroom. Weather, traffic, and unforeseen circumstances (such as other’s accidents/construction) can all play an integral role on a collection’s actual performance. It is the operator’s responsibility to not only determine the collection route within the designated collection area, but plan and assess all other extenuating circumstances that may impact the project’s requirements. The operator must be mindful of state and local laws, Michael Baker’s own safety rules and guidelines and staying within the designated project’s required accuracy and information specifications. Once a new operator has a few successful collections under his or her belt, they are fully integrated with collection planning, extraction and post processing of data including Continuously Operating Reference Station (CORS) data retrieval among other processing demands.

A Mobile LiDAR operator’s training is never fully complete. After two years of field experience I still find myself learning something new to share with others on our team each and every day. With constantly updated software, new, dynamic projects and the evolving LiDAR technology we adapt to such demands to keep abreast with application of this technology. Our work produces exciting new challenges every day. We will continue to meet and exceed our client’s expectations with exemplary collection practices and high quality data. With the proper training, order of operations, superior support staff and our senior leadership our operators will continue to excel both in and out of the trucks.

Cheers,

Jack

Jack King is Senior Mobile LiDAR Operator with Michael Baker International's Mobile LiDAR Center of Excellence. He has racked up more miles and projects than any other operator and can error handle with the best attitude and composure imaginable!

Thursday, September 29, 2016

As Seen on TV

The Mobile LiDAR team at Michael Baker International had the

distinct pleasure of being showcased on the latest episode of Worldwide Business with kathy ireland®. The segment, which aired on Sunday, September

25th on Fox Business Network, featured Peter Bonne, CEO of Orbit GT®. As you’ve seen in previous posts (Picture

of the Week and LiDAR

Data & Orbit GT), Michael Baker utilizes Orbit’s Content Manager, Asset

Inventory and Publisher software applications to exploit LiDAR and panoramic

imagery through our own web-portal.

|

| A look inside one of Michael Baker's Mobile LiDAR vehicles. |

|

| Michael Baker’s Bob Hanson discusses the role of Geospatial data in managing our Nation’s infrastructure. |

Our LiDAR operations have employed Orbit GT’s software for the

past year. Publishing spherical imagery

and LiDAR data has become a routine deliverable to our clients. By offering the

data in an “easy to use” application our clients are empowered to make timely decisions

without overwhelming them with “Big Data.”

|

| A view of the Orbit GT client application and published data as viewed through our web portal. |

A low resolution video is provided:

To view this program in HD, go to: https://vimeo.com/kathyireland/review/174216940/f19246eb7d

Cheers,

Stephen

Tuesday, September 20, 2016

By the Numbers: Positioning and Navigation

- 4: Number of individual positioning systems equipped on each of our 4 Mobile LiDAR systems: 1 dual antenna GPS/GNSS; 1 military-grade Inertial Measuring Unit (IMU); 1 Distance Measuring Instrument (DMI); and 1 GPS for vehicle navigation.

- 200: Frequency at which the vehicle’s position is updated every second (Hz). The IMU fine-tunes initial positioning generated by the dual-antenna GPS/GNSS by combining readings attitude (pitch, yaw, roll) calculations with distance traveled (DMI) to produce an accurate position at 200 Hz.

- 1: Number of IMU’s onboard each Mobile LiDAR system. One of our four IMU’s is also used by the U.S. Military as part of the guidance system of a Patriot Missile. That system is regulated by the U.S. State Department through the International Traffic in Arms Regulations (ITAR) – needless to say, there’s a little bit of red tape to clear if we want to take that unit out of the country.

- 12: Number of miles of subterranean mine shafts surveyed during a previous project. The combination of the IMU and DMI allow our systems to perform accurate collections during sustained GPS-outages using dead reckoning.

- 1,024: Number of wheel rotation measurements performed every second. Our DMIs are directly affixed to the vehicle’s wheel to ensure reliable readings. Due the inherent positional errors with GPS the DMI is not only used to indicate accurate distance traveled, but also to alert the system when the vehicle is stopped - called the "Zero Update".

- 2: The fluctuation in tire pressure (lbs.) which will result in inaccurate distance measurements. During a collection, the DMI scale factor (a function of the tire's circumference) is constantly monitored and "calibrated" using other systems, including GPS.

Wednesday, September 7, 2016

Circling the answer through RANSAC

Here in Michael Baker's Mobile LiDAR Center of Excellence, we are routinely challenged with developing new ways to extract the most from our data. Our focus is to minimize the amount of human interaction required to extract a relevant piece of data from the voluminous point clouds we collect. Understanding our necessary and recurring requirements within automated processes is important to us for the types of products we deliver. Knowing requirements helps us to determine if we are in a “buy versus build” decision for a particular software automation task. Many software companies are developing robust commercial software tools for feature extraction from LiDAR point clouds. However, the rights to modify any commercially developed software and inherent intellectual property and licensing costs can make the “buy” decision onerous and costly for us.

Understanding the likely and underlying algorithms we’d choose to employ in any software we look to build, or buy and license is vital. As engineers, surveyors and subject matter experts with a deep awareness of LiDAR data and its processing we know what we want and need for automation. Knowledge and necessity are not mutually exclusive. They should optimally align to produce the best solutions. That Rolling Stones lyric comes to mind. Yet, we don’t agree with the song’s implied result when it comes to software: “You don’t always get what you want, but you get what you need.”

In the best case, we get what we want and also need as it comes to our requirements for LiDAR processing. Too many needs are fulfilled inefficiently with commercial software. We must avoid “kluge approaches” when fulfilling a specific software or task sequencing approach, so in house development allows us to fulfill these needs specifically and efficiently in our LiDAR processing.

Understanding the likely and underlying algorithms we’d choose to employ in any software we look to build, or buy and license is vital. As engineers, surveyors and subject matter experts with a deep awareness of LiDAR data and its processing we know what we want and need for automation. Knowledge and necessity are not mutually exclusive. They should optimally align to produce the best solutions. That Rolling Stones lyric comes to mind. Yet, we don’t agree with the song’s implied result when it comes to software: “You don’t always get what you want, but you get what you need.”

In the best case, we get what we want and also need as it comes to our requirements for LiDAR processing. Too many needs are fulfilled inefficiently with commercial software. We must avoid “kluge approaches” when fulfilling a specific software or task sequencing approach, so in house development allows us to fulfill these needs specifically and efficiently in our LiDAR processing.

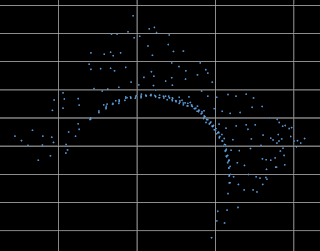

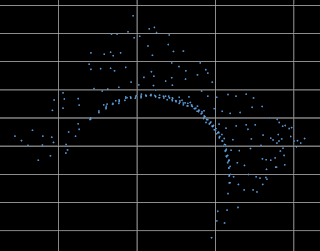

As an example let’s examine how we might fulfill a very repetitive task while using a computer to find the precise center, radius and circumference of a circle within the chaos of thousands of LiDAR points in a point cloud through a combination of geometry and algorithm design.

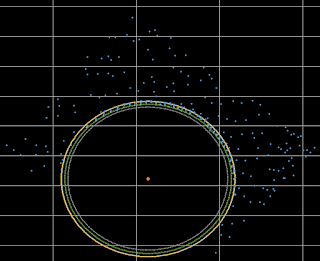

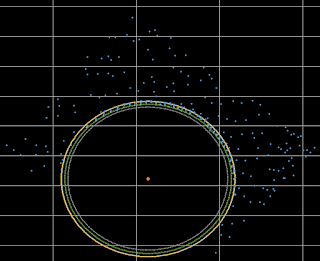

RANSAC (Random Sample Consensus) is an iterative based outlier detection method. The basic principle of which has been evolved to work with geometric equations allowing the system to determine the best fit circle within the LiDAR point data as well as locating the center of the best fit circle. The system creates “slices” through the points at a specified thickness in the vertical plane then determines the best fit circle and center point for each slice. Once we determine the location of a phenomena that might represent a circular object, we can use an automation tool to facilitate automatic extraction.

The advantages of such a tool include:

The advantages of such a tool include:

We continually focus on getting everything right with one right extraction process at a time. This RANSAC system of processing is one of many developments that we will continue to exploit which sets us apart, ensuring Michael Baker International is the first name in LiDAR.

Regards,

Sandor

Sandor Laszlo, PE is a Software Engineering Supervisor with Michael Baker's Mobile LiDAR Center of Excellence. Sandor's current focus is on the development of semi-automatous systems for extraction of features from LiDAR point cloud information.

RANSAC (Random Sample Consensus) is an iterative based outlier detection method. The basic principle of which has been evolved to work with geometric equations allowing the system to determine the best fit circle within the LiDAR point data as well as locating the center of the best fit circle. The system creates “slices” through the points at a specified thickness in the vertical plane then determines the best fit circle and center point for each slice. Once we determine the location of a phenomena that might represent a circular object, we can use an automation tool to facilitate automatic extraction.

The advantages of such a tool include:

The advantages of such a tool include:- Ability to calculate the taper of any circular object ( columns, posts, poles, water tanks, etc.) and project the taper to a point that may be obscured by an object in the LiDAR data

- Determining if an object is leaning by analyzing the center points of all the slices along the height of the object

- Reducing the human error of manual attempts to extract the circle and center points.

We continually focus on getting everything right with one right extraction process at a time. This RANSAC system of processing is one of many developments that we will continue to exploit which sets us apart, ensuring Michael Baker International is the first name in LiDAR.

Regards,

Sandor

Sandor Laszlo, PE is a Software Engineering Supervisor with Michael Baker's Mobile LiDAR Center of Excellence. Sandor's current focus is on the development of semi-automatous systems for extraction of features from LiDAR point cloud information.

Labels:

Application Development,

Guest Authors

Monday, September 5, 2016

Happy Labor Day!

Today we celebrate the contributions of the American Worker to our country’s success. All of our U.S. offices are closed this Labor Day in honor of those that have played a pivotal role in building our nation’s infrastructure. As we pack our whites and celebrate the unofficial end of summer, we’re also planning our continued deployment of innovative solutions to ensure “We Make a Difference”.

Today we celebrate the contributions of the American Worker to our country’s success. All of our U.S. offices are closed this Labor Day in honor of those that have played a pivotal role in building our nation’s infrastructure. As we pack our whites and celebrate the unofficial end of summer, we’re also planning our continued deployment of innovative solutions to ensure “We Make a Difference”.

Wednesday, August 31, 2016

By the Numbers: Lasers and Cameras

- 168: The number of Megabytes of data created EVERY SECOND by each of our Mobile LiDAR systems when we fire the lasers and cameras at their maximum rates.

- 150: Weight in pounds of each of our 4 Mobile LiDAR systems.

- 35: Weight in pounds of each of the two onboard LiDAR sensors that comprise each of our systems. The solid, machined-aluminum chassis of each sensor doubles as a giant heat-sink to dissipate internal heat generated by the sealed unit.

- 2: Number of hours it takes to transfer and test one of our Mobile LiDAR systems from its regular vehicle mount to our boat or UTV.

- 1.2 Million: Number of discrete laser shots each of our Mobile LiDAR systems is capable of generating EVERY second.

- 4.8 Million: The astonishing number of measurements calculated by each LiDAR system every second. Each discrete laser shot can result in up to 4 returns (1st, 2nd, 3rd, and Last).

- 5: The number of primary camera units deployed with each Mobile LiDAR system. Four cameras can maneuvered to a myriad of locations along the vehicle and can simultaneously fire up to 2 frames per second (fps). The 5th camera is our Ladybug 360 spherical unit, which can fire at a rate of 3 fps.

- 6: The number of individual cameras that are housed in the Ladybug spherical camera system – software automatically stitches the individual images together for spherical viewing. The versatile spherical camera unit also produces individual calibrated images that can be used to colorize the corresponding LiDAR point-cloud, or loaded into 3rd-party applications (such as our Orbit WebViewer) for overlay of the point-cloud.

Friday, August 26, 2016

Picture of the Week: Orbit RGB Point Cloud

A couple months ago we discussed how we served LiDAR data in Orbit GT through the Baker Enterprise Architecture for Spatial Technology (BEAST). Below are some images of how we are using RGB colorization in Orbit. The colorization of the point cloud has evolved from using two cameras with our first Optech Lynx v200 system to the integration of the LadyBug spherical camera - revisit our post from 2010 called Coloring the Cloud.

|

| The RGB colorized point cloud is seamlessly integrated with the LadyBug panoramic imagery after calibrating in Optech's LiDAR Mapping Suite (LMS) software. |

|

| Escaping the view using the panoramic imagery, the user can work directly with the colorized point cloud. |

|

| The blue points represent camera exposures that the technician can "step into" for feature extraction and review of the panoramic imagery. |

Stephen

Wednesday, August 24, 2016

By the Numbers

- 4.5: Typical number of days an average project occupies a Mobile LiDAR equipment resource (mobilization, collection, and demobilization).

- 60-100: Number of miles 1 LiDAR system can regularly capture per day under normal driving conditions for urban and rural areas.

- 37,500: Average annual mileage travelled by each of our 4 LiDAR systems.

- Since purchasing our first Mobile LiDAR system:

- 200+: Number of completed projects;

- 29: Number of U.S. States in which we’ve performed collections. We also have multiple Countries under our belt as well;

- 25+: Departments of Transportation or Transportation Agencies for whom we’ve successfully completed projects;

- 400+: Miles of railway captured from Hi-Rail mounted equipment throughout several projects;

- Fostered tens of Millions in econmic impact;

- Coached numerous agencies through their development of Mobile LiDAR Guidelines; and,

- 13: The Baker’s Dozen: 13 Laws of Mobile LiDAR

Cheers!

Aaron

Wednesday, August 10, 2016

We Can’t Stop Imagining the Possibilities!

|

| Copyright, Hanna Barbera and Warner Bros. Entertainment, Inc. All Rights Reserved. |

To see the video of this Terrafugia vehicle in flight use this link: https://www.terrafugia.com/the-transition/ or https://www.terrafugia.com/

How does this sort of technology relate to Michael Baker? When our company entered the Mobile LiDAR market seven years ago, we spent a lot of time here at our company discussing, amongst our LiDAR team and clients, the real issues we encounter with occlusion of LiDAR from either the ground (mobile) or from an airplane (aerial). In either scenario, line of sight limitations won’t let us see the top of things from the ground, under things from very high in the air, or through things in either case. If only I could attach wings to our Mobile LiDAR vehicles! If only I could economically put a commercial LiDAR system on a vehicle like that envisioned by Terrafugia! Such a vehicle of course has to be engineered to configure its wings and propellers to consider the placement of LiDAR

and camera systems. But, I’m a bit ahead of the point I want to make with any emerging, converging technologies.

and camera systems. But, I’m a bit ahead of the point I want to make with any emerging, converging technologies.While I patiently wait for a more visionary and technologically feasible solution for deploying high density, engineering-quality mobile LiDAR systems that can fly as well as be driven, I can now turn with some hope to Part 107 of the FAA’s implementation of commercial small unmanned aerial systems (sUAS) for interim possibilities. Keep in mind, at the top of my list of the impediments to complete success with any LiDAR approach is occlusion. Getting full 360 degree coverage of an object or area of interest is especially challenging with Mobile LiDAR projects, since some sites are inaccessible with driving. Roof tops on flat buildings are a practical impossibility. From the air, we can potentially collect data with sUAS using imagery and small LiDAR systems to fill those occlusion areas and data voids resulting from line of sight limitations with Mobile LiDAR systems. With sUAS we can fly low, hover and fly in a very controlled way to fill voids in Mobile LiDAR data. Temporal updates for specific areas of interest (e.g., change) can also be performed cost effectively with sUAS against an existing point cloud previously acquired with LiDAR.

As a long term FAA Section 333 exemption holder for commercial sUAS operations, Michael Baker can now look at the certain less restrictive conditions and the possibilities and opportunities created in Part 107 (https://www.faa.gov/news/press_releases/news_story.cfm?newsId=20515).

Two areas that catch one’s imagination are:

- No operations from a moving aircraft.

- No operations from a moving vehicle unless the operation is over a sparsely populated area.

For the first of these, I am sure there is a reason why somebody might or could want to fly a sUAS from another flying aircraft, perhaps attempting to fly and operate a sUAS while also flying in a hot air balloon comes to mind for some purpose (expanded line of sight).

I now know I can’t fly a sUAS from the Terrafugia TF-X. That fact might keep me from soon placing my order for one of those flying cars. I need to think through the impact of the sUAS limitation with my desired TF-X. But, the Terrafugia TF-X is so cool, anyway! I have to categorize this FAA limitation as a minor annoyance not to be able to fly my sUAS from the TF-X.

I still want to imagine a Mobile and Aerial LiDAR system on that TF-X flying car.

For the second FAA case of allowing operation of a sUAS from a moving vehicle, I think there are some possibilities for this application with Mobile LiDAR. This sort of flight operation must occur under the correct and safe circumstances. The FAA will apparently allow us to operate a sUAS from a moving vehicle under the right, approved scenarios and with an added exemption issued by the FAA and for specific area(s). This sort of exemption can be applied to rail lines and perhaps controlled roadways. I can’t yet imagine all the possibilities for us, yet. But, the marriage of integrated Mobile LiDAR and sUAS will happen very quickly here at our company. Soon our Mobile LiDAR systems will roll out on nearly all projects with their sUAS(es) as part of their compliment of equipment for survey control, imagery and LiDAR. Getting the remote Pilot – Small Unmanned Aircraft Systems Airman Certification comes next.

I’ll have more insights on that process later.

Cheers!

Bob

Robert Hanson is Senior Vice President and Michael Baker's National Practice Lead for Geospatial Information Technologies. Bob is known as a visionary and futurist within our ranks and was the driving force for Michael Baker's acquisition of our first Mobile LiDAR system in 2009.

Thursday, August 4, 2016

Throw Back Thursday

A recent article from POB quoting our very own Bob Hanson on "Tips for Managing Big Geospatial Data" got me thinking about an old post mentioning Zettabytes. The article written more than 6 years ago (long before we had 4 SG1 systems on the road) talks about the volume of data collected. Bob's reference to the size of data we collect today was not in our comprehension back then.

For Throw Back Thursday, I offer a picture of Michael Baker's first computer. (Mr. Baker is the gentleman with the striped suit.) I don't know the specifics of the computer pictured, but I doubt Mr. Baker could have ever envisioned the volume of data we're working with today.

Cheers!

Stephen

For Throw Back Thursday, I offer a picture of Michael Baker's first computer. (Mr. Baker is the gentleman with the striped suit.) I don't know the specifics of the computer pictured, but I doubt Mr. Baker could have ever envisioned the volume of data we're working with today.

Cheers!

Stephen

Labels:

Picture of the Week,

Throw Back Thursday

Thursday, July 28, 2016

Throw Back Thursday

For our first "Throw Back Thursday" post, we go all the way back to 2010 with the Dick Henderson Bridge project in St. Albans, WV. It was our first Mobile LiDAR collection from the water.

For our first "Throw Back Thursday" post, we go all the way back to 2010 with the Dick Henderson Bridge project in St. Albans, WV. It was our first Mobile LiDAR collection from the water. Our client already had a barge on-site to support inspection and other activities. Therefore, we were able to simply drive the vehicle onto the barge and collect the underside of the bridge in a matter of a couple hours. Using painted survey targets on the bridge, we seamlessly merged the data from the barge with data collected on the bridge. In a previous post titled "West Virginia - Preliminary Information", the trajectories from the two collections are presented.

As mentioned in Tuesday's post, it is rewarding to see the completed projects. The bridge officially reopened in October 2013, as covered by the Charleston Gazette Mail.

Cheers!

Stephen

Tuesday, July 26, 2016

Picture of the Week

My friends and coworkers know that when I travel with my

family, I prefer to drive rather than fly.

It’s not that my wife doesn’t know how to pack/dress to go through

security smoothly. It’s because I love

to see new places and stop at roadside attractions. We

ultimately endeavor to visit all 50 states together.

A trip last week to Traverse City, MI for the MAPPS Summer

conference afforded the opportunity to put more miles on the family car. While I don’t necessarily route our

trajectory through past Mobile LiDAR projects, we almost always hit one or two

along the way. Although many of the

projects have long been collected, processed and delivered, the remnants (targets) are

still visible – every 500’ – 1,000’.

|

| The white chevron target of a past Michael Baker Mobile LiDAR project is visible in the shoulder. |

Cheers!

Stephen

Friday, July 8, 2016

Pictures of the Week

Recently, we had the pleasure of performing a unique elevated rail collection. To capture the rail corridor, our system was installed on the clients' Hi-Rail equipped Kubota side-by-side.

The Kubota provided an ideal platform to perform the collection. The beautiful, clear blue skies yielded exceptional photographs - which were delivered in an online Orbit publication.

Above, the operator monitors the collection, examining real-time imagery, point cloud data and positional metrics. The driver had it easy with no traffic or steering to contend with.

Cheers!

Stephen

The Kubota provided an ideal platform to perform the collection. The beautiful, clear blue skies yielded exceptional photographs - which were delivered in an online Orbit publication.

Cheers!

Stephen

Monday, July 4, 2016

Happy Independence Day!

As we celebrate our nation’s independence this Fourth of July, we encourage you to reflect on the diversity of peoples, beliefs, cultures, traditions, and histories that have come together to make this great country. Enjoy your time with friends and family and have a safe and responsible Fourth!

The Mobile LiDAR Team

Thursday, June 30, 2016

Back in the Saddle

It’s not very common that I, or the rest of the LiDAR Center’s management team for that matter, get the opportunity to physically sit in the driver’s seat and be part of the daily logistics train. But as luck would have it, on two such occasions over the past year I’ve had the opportunity to road trip with a Mobile LiDAR system.

Operating 4 Mobile LiDAR units (see Launching a Fleet) gives us the ability to be in many more places than ever before, but that’s only possible if there are LiDAR technicians available to transition the units from project to project. Even the most dedicated staff need a couple days off between long deployments; so needless to say, these trips were born out of necessity.

It’s been a little over 8 years since I’ve had the opportunity to do any field work, but it didn’t take long to get right back into the swing of things. Logistical efficiency is the name of the game. The more efficiently we perform on the work site and move between projects, the more projects we complete each deployment cycle, and the more cost savings we pass along to our clients. Think of it as “Just in Time” surveying.

Often overlooked and frequently taken for granted are the intricacies associated with the transition of field equipment/personnel between projects. The majority of people give no more consideration to a mobilization event than the time it takes to briefly consider the 1-2 day line-item on a project’s Gantt chart. In reality it’s a well-choreographed ballet of driver swaps, pit-stops, bio-breaks, traffic avoidance, and ad-hoc photo-ops.

Mobilizations are all about time-management. More aptly, it’s all about minimizing the loss of time. Speed limits and known construction sites establish the baseline for maneuvering from A-to-B. Accidents, thunderstorms, low overhead clearances, impromptu parades, flat tires, ice fog, volcanic events, presidential motorcades, and the occasional late night burrito lurk beyond every bend in the road looking for the opportunity to delay your arrival (and yes, I’ve encountered all of these, and many more in my day).

Don’t fool yourself into thinking that the drivers’ job is just a mindless exercise of maintaining 10-and-2 on the wheel and keeping it between the lines. Every delay, regardless of severity, and every spotted mile-marker evokes a seemingly-constant mental recalibration of the projected arrival time and the logistical changes that need to be coordinated.

Each and every time the vehicle stops you lengthen the amount of time you’ll be on the road that day. And with a 3-foot tall set of equipment strapped to the roof, there’s no options for the driver-thru. So each trip quickly reverts to a game of “how long can I wait”.

Aaron

LiDAR Services Director

Operating 4 Mobile LiDAR units (see Launching a Fleet) gives us the ability to be in many more places than ever before, but that’s only possible if there are LiDAR technicians available to transition the units from project to project. Even the most dedicated staff need a couple days off between long deployments; so needless to say, these trips were born out of necessity.

It’s been a little over 8 years since I’ve had the opportunity to do any field work, but it didn’t take long to get right back into the swing of things. Logistical efficiency is the name of the game. The more efficiently we perform on the work site and move between projects, the more projects we complete each deployment cycle, and the more cost savings we pass along to our clients. Think of it as “Just in Time” surveying.

Often overlooked and frequently taken for granted are the intricacies associated with the transition of field equipment/personnel between projects. The majority of people give no more consideration to a mobilization event than the time it takes to briefly consider the 1-2 day line-item on a project’s Gantt chart. In reality it’s a well-choreographed ballet of driver swaps, pit-stops, bio-breaks, traffic avoidance, and ad-hoc photo-ops.

Mobilizations are all about time-management. More aptly, it’s all about minimizing the loss of time. Speed limits and known construction sites establish the baseline for maneuvering from A-to-B. Accidents, thunderstorms, low overhead clearances, impromptu parades, flat tires, ice fog, volcanic events, presidential motorcades, and the occasional late night burrito lurk beyond every bend in the road looking for the opportunity to delay your arrival (and yes, I’ve encountered all of these, and many more in my day).

Don’t fool yourself into thinking that the drivers’ job is just a mindless exercise of maintaining 10-and-2 on the wheel and keeping it between the lines. Every delay, regardless of severity, and every spotted mile-marker evokes a seemingly-constant mental recalibration of the projected arrival time and the logistical changes that need to be coordinated.

Each and every time the vehicle stops you lengthen the amount of time you’ll be on the road that day. And with a 3-foot tall set of equipment strapped to the roof, there’s no options for the driver-thru. So each trip quickly reverts to a game of “how long can I wait”.

- Can the radio go loud-enough to drown-out the incessant squeaking/rattling coming from the toolbox that vibrated loose?

- Will the fumes in the tank get me to the travel plaza at the next exit that has a deli and a Dunkin Donuts, or do I pull over now at Mr. Bob’s Country Gulp-n-Guzzle with the slowest pumps known to man?

- Can I make it to the in-and-out convenience of the Rest Stop, and what are the chances it’s closed due to budgetary cutbacks?

Aaron

LiDAR Services Director

Thursday, June 23, 2016

Esri International User Conference

Come visit us at the 2016 Esri International User

Conference in beautiful San Diego.

Michael Baker will be exhibiting at the IUC (Booth #2506) June

28-30. If you can’t find our booth by

number, just look for the 8’x10’ image (see below) of our all-in-one Mobile

LiDAR + LCMS + GPR equipped vehicle. Both

Bob Hanson (GIT National Practice Lead) and Aaron Morris (LiDAR Services

Director) from our National LiDAR Center will be in attendance, as well as

numerous representatives from offices across the country, so take a moment and

stop by to learn more about Mobile LiDAR or any of the other world class

services we provide.

Cheers!

Stephen

Cheers!

Stephen

Friday, June 17, 2016

LiDAR Data and Orbit GT

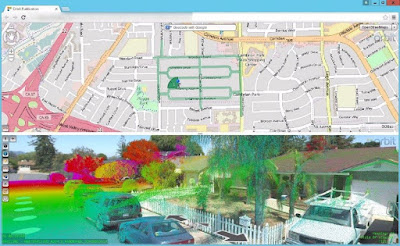

Now that you’ve got Gigabytes or Terabytes of processed Mobile LiDAR data, what do you do with it? Experienced end-users may have multiple tools to view and manipulate Mobile LiDAR data; but what about the average John Q. Public that doesn’t have tens-of-thousands of dollars to dump into software and training? To help our clients maximize their resources we’ve implemented a web-based solution on our BEAST environment (see Belly of the BEAST) that leverages the Orbit GT framework to link panoramic imagery, GIS/CAD features, and LiDAR point clouds into a single integrated solution that can be accessed from any of the most popular internet browsers.

By publishing the LiDAR data with Orbit end users are provided a user-friendly platform to view, collect, and interact with various forms of field-collected data. The configurable user environment typically contains two imbedded, user-scalable windows for an overview map (top section) and the panoramic imagery and LiDAR point cloud (bottom section). The overview map supports OpenStreetMap, which provides an excellent backdrop for the overlay of panoramic image locations and available GIS data. Similarly, GIS data can also be overlain on panoramic imagery / point cloud window(s), provided valid elevations are available in the GIS.

Other basemap functionality includes the ability to geocode addresses using Google’s geocoding engine, search by GIS object, and search by X,Y coordinates. The Search by Object tool is particularly helpful as it will search all attributes within the selected layer, not just on a single column.

The panoramic imagery / point cloud section also has a robust selection of tools through which the user can toggle on/off layers and interrogate GIS data, as well as the ability to open multiple viewing windows to simultaneously observe the same location from various perspectives. 360-degree pan/zoom functionality is standard, as are measurement tools including: positional location, distance, line (single and multi-segment), area, and volumetric calculations.

The beauty of the solution is the ease of use. Anyone that’s ever used an online map will be self-navigating and making meaningful observations within minutes – and all without any special software or any required training.

Stay tuned, I’ll share more content in the future about this and other technology being leveraged by our clients.

Regards,

Scott

Scott Peterson is a Systems Supervisor in Michael Baker's Ridgeland, MS office. His responsibilities include Database Administration for the BEAST, data maintenance and publishing for use by Michael Baker's staff and clients.

Thursday, June 9, 2016

Origin of a Point Cloud

Wikipedia has defined a “Point Cloud” as “a set of data points in some coordinate system”. In a three-

dimensional coordinate system each point is commonly defined by an X, Y, and Z value, and is often employed to represent the surface of an object. Point cloud geometry is often referred to, rather mistakenly, as LiDAR. LiDAR is a technology that can be used to make point clouds; so measurements produced with LiDAR technology is more aptly known as LiDAR data. Most commonly, point clouds are the result of data being output by 3D scanners. Aerial and Terrestrial LiDAR sensors are two such examples of 3D scanners that perform a large number of measurements on an object's surface to output a point cloud, but as you’ll read, point clouds may originate from various other sources and technologies.

Photogrammetric Detection and Ranging (PhoDAR) is an alternative technology to conventional photogrammetry and LiDAR to generate point clouds. Though, PhoDAR and LiDAR are both capable of producing point clouds, the primary difference being PhoDAR uses photographic data (i.e. pictures) collected with a camera to generate a point cloud, whereas LiDAR involves the collection of data measured directly from the reflection of an object using a laser.

Another technology from which topographical point clouds are regularly created is IFSAR (Interferometric Synthetic Aperture Radar). . IFSAR sensors are typically flown in fixed-wing aircraft or mounted to satellites, and primarily uses X-band data of the electromagnetic spectrum to perform measurements. IFSAR data collection involves placing two radar (radio detection and ranging) antennas on the vehicle such that one antenna transmits a radar beam, and then both antennae receive the radar beam reflected from the target (usually the earth’s surface). Captured signals are combined with aircraft telemetry and positional data are processed to generate an interferogram, which is employed to generate elevation products.

Sound Navigation and Ranging (SONAR) technology uses the propagation of sound in an underwater environment to target objects. It is most commonly used to in the surveying profession to determine water depth (bathymetry). Sonar is applied to water-based activities because sound waves attenuate (taper off) less in water as they travel than do radar and light waves.

In future posts I’ll provide detailed analysis of the pros/cons, uses, and accuracies of the various technologies, but for now, the following table provides a brief overview of each.

Cheers!

Srini

Photogrammetric Detection and Ranging (PhoDAR) is an alternative technology to conventional photogrammetry and LiDAR to generate point clouds. Though, PhoDAR and LiDAR are both capable of producing point clouds, the primary difference being PhoDAR uses photographic data (i.e. pictures) collected with a camera to generate a point cloud, whereas LiDAR involves the collection of data measured directly from the reflection of an object using a laser.

Another technology from which topographical point clouds are regularly created is IFSAR (Interferometric Synthetic Aperture Radar). . IFSAR sensors are typically flown in fixed-wing aircraft or mounted to satellites, and primarily uses X-band data of the electromagnetic spectrum to perform measurements. IFSAR data collection involves placing two radar (radio detection and ranging) antennas on the vehicle such that one antenna transmits a radar beam, and then both antennae receive the radar beam reflected from the target (usually the earth’s surface). Captured signals are combined with aircraft telemetry and positional data are processed to generate an interferogram, which is employed to generate elevation products.

Sound Navigation and Ranging (SONAR) technology uses the propagation of sound in an underwater environment to target objects. It is most commonly used to in the surveying profession to determine water depth (bathymetry). Sonar is applied to water-based activities because sound waves attenuate (taper off) less in water as they travel than do radar and light waves.

In future posts I’ll provide detailed analysis of the pros/cons, uses, and accuracies of the various technologies, but for now, the following table provides a brief overview of each.

Technology

|

Coverage

|

Accuracy

|

Use of Technology

|

Terrestrial LiDAR (Mobile or Static)

|

Small-to-Medium area projects

|

1cm

|

Buildings, Corridor mapping, Asset Inventory, Engineering Design

|

Aerial LiDAR

|

Large area

projects, in varied terrain conditions

|

10 cm

|

Flood plain mapping, Disaster Management, Transportation and Engineering design, Impervious surface mapping, vegetation mapping

|

PhoDAR

|

Medium-area projects

|

15+ cm (dependent on GSD)

|

Same as above

|

IFSAR

|

Large area projects in varied terrain conditions

|

30 cm

|

Same as above

|

SONAR

|

Small-to-Medium area projects

|

5-10cm

|

Underwater studies, dredging, navigation

|

Cheers!

Srini

Labels:

Ask the Doctor,

Guest Authors,

Miscellaneous,

Mobile LiDAR 101

Friday, June 3, 2016

Belly of the BEAST

|

| A bank of 2 TB hard drives in our Data Center. |

The BEAST hosts a variety of tools that are available to all Michael Baker offices and enables our staff to collaborate on projects in an effective and efficient environment across offices, regions and even continents.

Michael Baker employees typically access the BEAST via Citrix MetaFrame interface. This allows users to access the data through a thin client with all data and software residing “in our private cloud”.

Software and database solutions that we use for LiDAR processing and feature extraction or GIS product production include Optech’s LiDAR Mapping Suite (LMS), ArcGIS (in multiple flavors), Orbit GT, SQL Server, FME, MicroStation, GeoCue, TopoDOT and LizardTech GeoExpress along with custom developed applications. By utilizing fully virtualized environments, the BEAST allows for unparalleled flexibility to rapidly scale additional resources for large-scale project delivery. In many cases, we will also utilize Amazon and Microsoft Cloud services for surge needs; while we continually evaluate overall cost effectiveness of those and other cloud platforms considering the practicalities of uploading and storing terabytes of LiDAR data each day to a cloud service.

|

| Two 56 TB storage servers at a local production office. |

Cheers!

Art

Art Morris is a Systems Analyst in Michael Baker's Harrisburg

office. Art joins the Mobile LiDAR team from IT Services, to focus his talents on

the acquisition, transfer, and processing of the vast amount of LiDAR data

collected by our vehicles.

Art's IT background helps him to act as a liaison between departments, offices and regions, to ensure synergistic collaboration between the Mobile LiDAR team and Michael Baker's IT organization.

Art's IT background helps him to act as a liaison between departments, offices and regions, to ensure synergistic collaboration between the Mobile LiDAR team and Michael Baker's IT organization.

Monday, May 30, 2016

Memorial Day

On behalf of Michael Baker International, the Mobile LiDAR Team would like to take the opportunity this Memorial Day to recognize and remember our country’s military members who made the ultimate sacrifice to protect the very freedoms we enjoy today. As you spend this day with loved ones, please think about those who fought and gave their lives to secure the liberties that allow us to live, work and make a difference.

As a firm that employs veterans from many countries and delivers mission-critical services in support of our country’s military around the globe, we’d like our active duty, reserve, guard and contractor friends and family to know they are in our thoughts during their extended deployments and separation from friends and family.

If you are able and so inclined, please consider making a contribution to organizations that support the surviving spouses and children of our fallen heroes. Such organizations include (but not limited to):

- Special Operations Warrior Foundation - http://www.specialops.org/

- Children of Fallen Patriots - http://www.fallenpatriots.org/

- Intrepid Fallen Heroes Fund - http://www.fallenheroesfund.org/

Thank you,

The Mobile LiDAR Team

Thursday, May 26, 2016

Launching a Fleet

It’s been a while since our last posting, and we’ve certainly appreciated your patience during this brief hiatus – but rest assured, plenty of new content (and contributors) is on the way. The expansion of our Fleet –4 Mobile LiDAR systems, plus an integrated Laser Crack Measurement System (LCMS), plus an integrated Ground Penetrating Radar (GPR), plus multiple static LiDAR units – temporarily diverted our attention from our social media content while we focused on scaling other areas of the operation to handle the workload simultaneously coming from four systems. Luckily our faithful followers have been treated to a regular stream of content to Instagram thanks to our new Fleet Manager.

It’s been a while since our last posting, and we’ve certainly appreciated your patience during this brief hiatus – but rest assured, plenty of new content (and contributors) is on the way. The expansion of our Fleet –4 Mobile LiDAR systems, plus an integrated Laser Crack Measurement System (LCMS), plus an integrated Ground Penetrating Radar (GPR), plus multiple static LiDAR units – temporarily diverted our attention from our social media content while we focused on scaling other areas of the operation to handle the workload simultaneously coming from four systems. Luckily our faithful followers have been treated to a regular stream of content to Instagram thanks to our new Fleet Manager.Quadrupling your collection capacity in less than 8 months looks like a pretty straight forward process on paper, but launching a fleet of the most sophisticated mobile mapping systems at times felt like we were choreographing logistics for NASA’s Mission Control. Four times the number of collection systems means four times the amount of logistics, maintenance, personnel, proposals, storage capacity, and last but not least…Data!

It’s no small feat effectively handle up to 4 Terabytes of new data each and every day. Any way you slice it, that’s a lot of data. So there’s your parting thought for the day – How would you transfer 4 TBs of data from various locations throughout North America on a daily basis?

Cheers!

Aaron

LiDAR Services Director

Monday, January 25, 2016

Direction of our "Light"

No longer only a tool for science, landform mapping and Geomatics Engineering, we have expanded our LiDAR (Light Detection and Ranging) usage by further analyzing, managing and manipulating the LiDAR data sets across a host of practical applications. This understanding of how to fully utilize and interact with LiDAR data is allowing us to design and create structures and systems – notably in the building, infrastructure and in situ environments – that are safer and more resilient.

But what’s fascinating is that we are still just beginning to achieve LiDAR’s potential for information gathering and usage. One emerging market that Michael Baker is focusing on is in enabling autonomous vehicles while building safer, smarter, real-time information systems within our transportation networks. The impact and applications for this type of ubiquitous, low-cost form of mass-produced LiDAR technology associated with automotive, rail, airborne, marine and other vehicles can change the way the world moves people and things.

The LiDAR data we collect at Michael Baker is of a very precise and dense variety. We apply LiDAR to the purpose of very selective illumination of phenomena in the line-of-sight of our sensor systems. We are selective in where and how we deploy our systems and we carefully plan collections. We primarily direct our LiDAR sensors at our customers’ infrastructure or assets for the comprehensive collection of a point cloud that will be analyzed to extract very specific information. Combined with the acquisition of panoramic and other imagery, our LiDAR and imagery data becomes quite massive in terms of the individual artifacts of data created within the collection process. Now we’re developing methods and algorithms that interact directly with these point clouds to perform conformity analysis with design standards and to analyze stress and perhaps load forecasting on infrastructure. This is the way we can extend the potential for that infrastructure though effective operation and maintenance practices, as well as predict the infrastructure’s ability to bear existing or additional demand loads.

With our Mobile LiDAR capabilities a single vehicle has the potential to collect in excess of a terabyte of data each day. Billions of LiDAR shots are recorded, tens of millions of photographs are taken and hundreds of thousands of individual LiDAR-based files are generated in a relatively short time period as part of the overall process of creating LiDAR deliverables for a typical project. We currently operate four extraordinarily hi-tech Mobile LiDAR systems, running a collective 800 days per year. We annually collect LiDAR to create more than a petabyte of raw engineering quality data to produce discrete, extracted information about specific infrastructure, assets or ecosystems. After collection, we may double the amount of data we produce and manage for the deliverables we derive from the raw LiDAR or images. Accurately and cost-effectively creating and managing such information is a constant challenge for a large scale LiDAR operation such as ours.

The laser sensors we employ are generally indiscriminate when collecting data. A pulse is emitted and returned. We collect everything in the line-of-sight potential of our eye-safe lasers with great precision. Then we analyze the aggregation of billions of LiDAR points within a dataset to determine any phenomena and its relevancy to an intended purpose.

As we continue to find new data to mine and explore all of the possibilities that LiDAR technology affords the transportation industry, it’s exciting to ponder the industry’s evolution and what the future looks like.

I invite you to join me at the 2016 MAPPS Winter Conference for a presentation titled: “Big Data or Data That’s Big? The Pervasiveness of LiDAR in the Approaches to Engineering” as I am further addressing these topics and how we are managing data. And, continue to follow this blog for future insights.

But what’s fascinating is that we are still just beginning to achieve LiDAR’s potential for information gathering and usage. One emerging market that Michael Baker is focusing on is in enabling autonomous vehicles while building safer, smarter, real-time information systems within our transportation networks. The impact and applications for this type of ubiquitous, low-cost form of mass-produced LiDAR technology associated with automotive, rail, airborne, marine and other vehicles can change the way the world moves people and things.

|

| What you see is what you get (WYSIWYG) with Mobile LiDAR. Completely immersive scenes are generated along transportation corridors for an array of applications. |

|

| Critical infrastructure is accurately mapped with application of sound surveying principles. |

The laser sensors we employ are generally indiscriminate when collecting data. A pulse is emitted and returned. We collect everything in the line-of-sight potential of our eye-safe lasers with great precision. Then we analyze the aggregation of billions of LiDAR points within a dataset to determine any phenomena and its relevancy to an intended purpose.

|

| The use of highly detailed Mobile LiDAR datasets provide the mechanism for feature extraction and attribution when used in conjunction with 360° spherical photography. |

I invite you to join me at the 2016 MAPPS Winter Conference for a presentation titled: “Big Data or Data That’s Big? The Pervasiveness of LiDAR in the Approaches to Engineering” as I am further addressing these topics and how we are managing data. And, continue to follow this blog for future insights.

Cheers!

Bob

Subscribe to:

Posts (Atom)